Crusher wear parts selection is the core factor that determines wear life, downtime frequency, and cost per ton in impact and sand-making circuits. This guide compares VSI ROS (rock-on-steel) and HSI impact crushers from an engineering wear perspective, focusing on failure mode, material suitability, and practical replacement strategy. If you are evaluating crusher wear parts for different feed types (limestone, granite, basalt, river gravel, recycled concrete), the key is to match hardness and microstructure to abrasion/erosion dominance, while keeping geometry and fit unchanged.

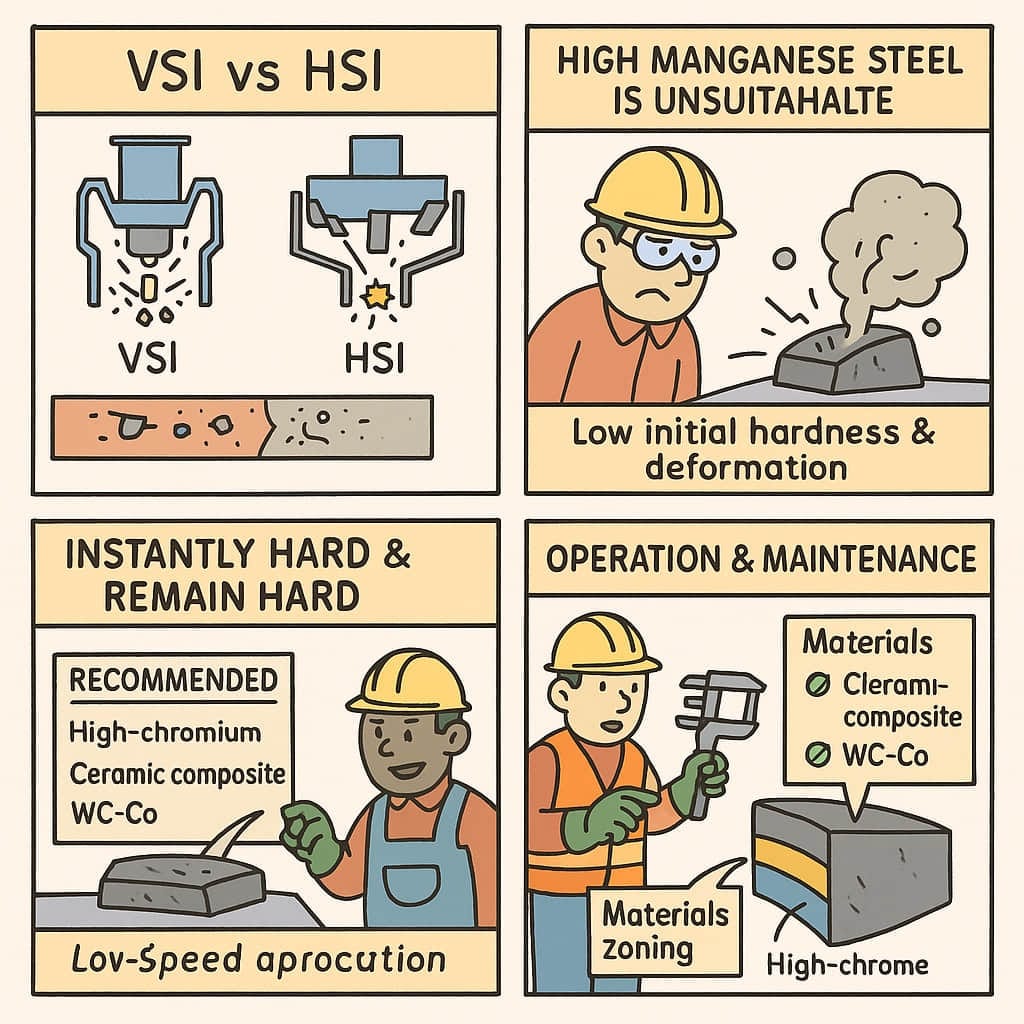

Working Principle Overview

| Category | VSI ROS (Rock-on-Steel) | HSI (Horizontal Shaft Impactor) |

|---|---|---|

| Working Principle | High-speed vertical rotor hurls material against steel anvils | Blow bars on a horizontal rotor strike material onto impact aprons |

| Typical Feed Size | ≤ 75 mm | Primary: ≤ 1 m; Secondary: ≤ 200 mm |

| Final Products | 0–10 mm manufactured sand, cubical aggregates | 0–40 mm aggregates and recycled material |

| Key Wear Parts | Rotor tips, anvils/anvil rings, wear plates | Blow bars, impact aprons, side liners |

| Wear Materials | WC-Co tips; Cr26 or Cr26 + ceramic anvils | High-chromium iron, martensitic or ceramic composite bars |

Why High Manganese Steel Fails in VSI Crusher Anvils

Low Initial Hardness

Hadfield manganese steel has an as-cast hardness of only ~187 BHN (~10 HRC), far below what’s needed for effective erosion resistance.

Requires Work Hardening – But VSI Conditions Don’t Allow It

This steel depends on impact >250 MPa to harden its surface to ~550 BHN. However, VSI machines operate with high-speed, fine particle impacts — the contact time is too short to trigger work hardening.

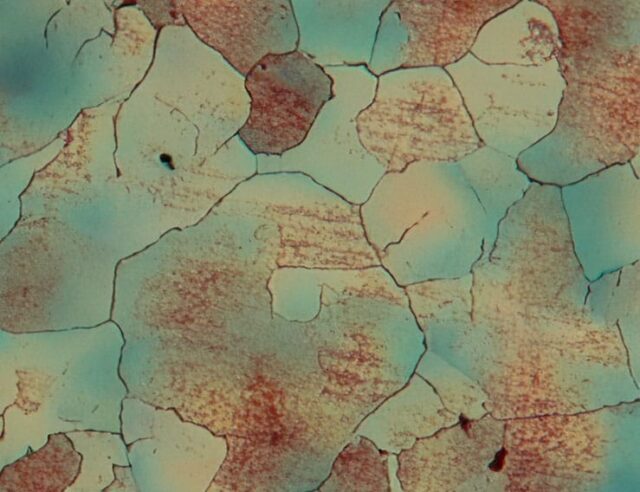

Poor Erosion Resistance

Comparative wear testing shows that Cr26 high-chromium white iron, due to its M₇C₃ carbide microstructure (1050–1500 HV), vastly outperforms hardened manganese in erosion conditions.

Prone to Plastic Deformation

Manganese steel deforms under high-speed particle erosion, disrupting internal flow paths and increasing machine wear and downtime.

High Production Risks and Cost per Ton

Due to complex geometry, manganese anvils suffer from high casting defect rates. Combined with short lifespan and frequent replacement, this increases operating costs significantly.

Recommended Wear Materials for VSI & HSI Crushers

| Component | Recommended Material | Hardness / Features | Best Use Case |

|---|---|---|---|

| Anvil / Anvil Ring | Cr26 High-Chromium Iron | 60–64 HRC; Carbides >1050 HV | Standard to high abrasion |

| Cr26 + Ceramic Composite | Surface >70 HRC; 1.5–2× lifespan | Very abrasive feeds (e.g., basalt) | |

| Rotor Tip | WC‑Co (Tungsten Carbide Bar) | 90–92 HRA; high toughness | Deep-cavity VSI, >70 m/s tip speed |

| HSI Blow Bar | Cr26 High-Chromium Iron | 60–65 HRC; brittle | Secondary crushing, limestone |

| Martensitic Steel | 45–55 HRC; impact-tough | Recycled concrete with rebar | |

| Ceramic Composite (Cr or Martensitic Base) | Extended wear life | High-abrasion, recycled aggregates |

How to Choose Crusher Wear Parts for Different Feed Materials

When selecting crusher wear parts, first classify the dominant wear mechanism: erosion (fine, high-velocity particles), abrasion (high quartz, sliding contact), or impact-dominant fracture (large feed, tramp metal, rebar). In VSI ROS, erosion and micro-chipping are usually dominant, so “always-hard” materials are preferred: Cr26 high-chromium iron for anvils and wear plates, and WC-Co for rotor tips. In HSI, the mechanism shifts with application: limestone and low-contaminant aggregates favor Cr26 blow bars for maximum wear life, while recycled concrete, mixed feed, or occasional tramp metal favors martensitic or composite bars to prevent catastrophic breakage.

A practical decision method is cost-per-ton, not just wear life. If the plant has stable feed and predictable wear, move to higher-hardness options (Cr26, ceramic composite zoning). If the plant has variable feed, frequent interruptions, or high risk of uncrushables, prioritize toughness (martensitic base, composite solutions) to reduce unplanned shutdowns. For abrasive basalts or high-silica river gravel, ceramic composite anvils or zoned wear packages can extend service life, while keeping the original anvil carrier geometry unchanged.

Finally, confirm three constraints before ordering crusher wear parts: (1) fit-up and tolerance to avoid stress concentration, (2) heat-treatment consistency to stabilize hardness, and (3) spare strategy (center-zone premium, edge-zone standard) to optimize total wear cost.

Operation & Maintenance Tips

-

Maintain 35–45 mm gap between rotor exit and anvils to ensure proper impact angles.

-

For sticky or high-impact feeds, use martensitic liners in high-stress zones.

-

Optimize cost and wear life by using ceramic composite in the impact center and Cr26 iron on the edges (zoning strategy).

Conclusion: Use “Always-Hard” Materials in VSI Applications

Manganese steel is unsuitable for VSI anvils due to:

-

Low initial hardness,

-

Inability to harden under VSI conditions,

-

Poor resistance to high-speed erosion, and

-

High deformation and casting defect rates.

Instead, industry best practices show that using Cr26 high-chromium iron, ceramic composites, or tungsten carbide tips:

-

Increases wear life by 2–4×,

-

Reduces downtime,

-

Lowers cost per ton processed.